Researchers at the Australian National University say new technologies that allow hydrogen to be produced directly from solar energy – skipping the need for expensive electrolysers – could be the pathway to low-cost renewable hydrogen supplies.

In new research published in the journal Advanced Energy Materials, the ANU research team has developed new “photoelectrode” designs, which could be a critical step towards high efficiency and low-cost renewable hydrogen production.

Conventional solar cells use semiconductor materials to convert sunlight into electric current. Over the last few decades, advances in solar cell designs have seen solar technologies established as one of the cheapest sources of electricity generation while having virtually no emissions footprint.

Researchers have sought to adapt solar cell technologies so that rather than producing an electric current, the captured solar energy could be used to drive chemical reactions, including chemical reactions that can extract hydrogen from water.

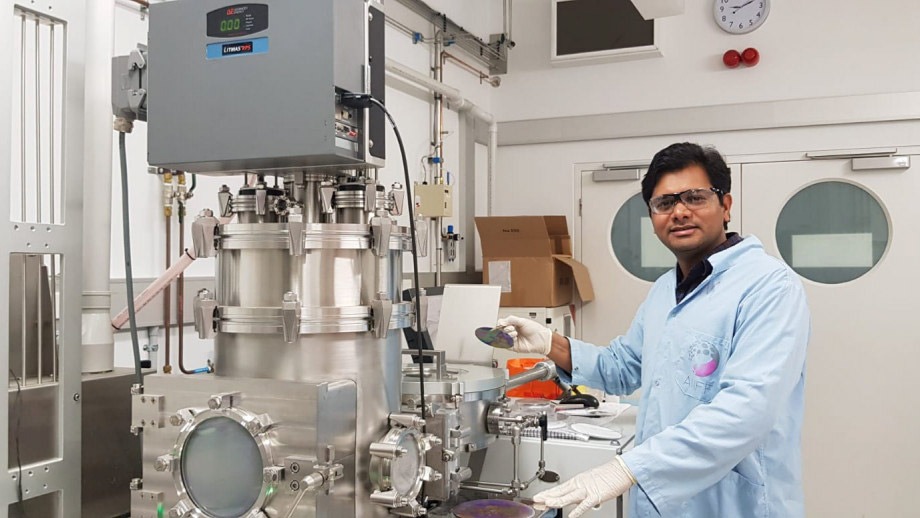

The ANU’s Dr Siva Karuturi, a co-author of the research, explained that the photoelectrodes being developed at the university create the potential for conventional solar cell technologies to be adapted for use in hydrogen production.

“Solar cells turn solar energy into electricity. Photoelectrodes can go a step further to directly convert sun energy into storable chemical fuels such as hydrogen,” Dr Karuturi said.

Previous attempts at producing the solar-to-hydrogen photoelectrodes found that they were vulnerable to degradation, making them unsuitable for large-scale commercial deployment.

But the ANU research team has sought to solve this problem by “de-coupling” the electrodes from the chemical reactions that led to their degradation, recognising the potential for the direct production of hydrogen from solar energy to provide low-cost supplies of hydrogen that could be stored and used as a dispatchable supply of energy.

“While this is an enticing prospect to address the intermittency problem, it remained a challenge to construct a photoelectrode that is both efficient and stable for practical operation,” Dr Karuturi added.

“This works opens up a pathway to transform rooftop PV cells into solar water splitting cells that produce green hydrogen. This could be a crucial step in addressing the intermittency of renewables and accelerate our transition to net-zero emissions.”

The ANU research team developed an innovative process of combining photoelectrodes with “cocatalyst foils”, which had the effect of shielding the photoelectrodes from chemical degradation, allowing them to be used for hydrogen production with a significantly lower risk of them being rendered unusable by corrosion.

“In this work, we demonstrate the use of cocatalyst foils for stabilising photoelectrodes while attaining high water splitting efficiencies, achieved first by depositing catalysts on metal foils prior to device fabrication and second by protecting photoabsorbers from corrosive solution during operation,” Dr Karuturi said.

“The catalytic interface is therefore fully-decoupled from the photoabsorber during both fabrication and operation. We also show that the approach can be used with other proven PV materials to realistically attain high solar-to-hydrogen efficiencies approaching theoretical limits.”

The conventional approach to producing renewable hydrogen sees renewable electricity supplies, such as from wind and solar farms, used to power an electrolyser that produces hydrogen by passing electricity through water molecules, separating the hydrogen and oxygen atoms.

But the new technologies being developed at the ANU could allow solar energy to power lower-cost chemical reactions that produce hydrogen, allowing the electrolysis process to be skipped altogether.

“Green hydrogen can be produced from renewable energy-driven electrolysis but is not currently competitive with fossil fuel sources of hydrogen. Instead, we are looking at new ways of producing hydrogen directly from sunlight and water,” Dr Karuturi added.

“In direct solar hydrogen production, sunlight provides the energy to drive the water-splitting redox reaction – via the photovoltaic effect and catalysis – resulting in hydrogen production in a single integrated system. ”

The ANU research team previously set new energy efficiency records for direct solar-to-hydrogen production, with efficiencies exceeding 20 per cent.

Lies, myths and greenwashing. Good independent journalism is time-consuming and costly. But small independent media sites like RenewEconomy have been excluded from the tens of millions of dollars being handed out to big media companies from the social media giants. To enable us to continue to hold government and business to account, to cut through the lies and the misinformation about the renewable transition, and to help expand our work on giving broad coverage to the exciting breakthroughs, advances and opportunities of the green energy transition, you can make a voluntary donation here. This will help ensure we can continue to offer the service free of charge and to as wide an audience as possible. Thank you for your support.